![]()

Adr :industrial zone, shanghai

Phone : +86 18221614363

Email : candymachinery@qq.com

Tel : +86 18221614363

processing capacity:50-1200kg/h

Application scope:gummy

Product introduction: Gummy candy production line is mainly used for gummy candy making. It integrates mechanical, electric, compressed air, and automatic control. feature is its high capacity, high quality

Automatic Depositing Gummy Production Line

Gummy candy production line is mainly used for gummy candy making. It integrates mechanical, electric, compressed air, and automatic control. feature is its high capacity, high quality, various products design, easy operation, reliable structure design, and high automatic grade. It can not only produce transparent gummy candy, double colors candy, double layers with double flavors candy, center filling candy, but also whirl designed product with multiple colors and tastes.

★The sanitary structure designed and manufactured meets GMP requirements.

★PLC /programmable process control available for candy vacuum cooking temperature and time, depositing temperature and depositing speed.

★LED touch screen displays process flow and realizes easy operation.

★Rationed filling and mixing of essence, pigment and acid solution can be completed on the line.

★The conveying chain, cooling system and double de-molding device guarantee the de-molding of candy.

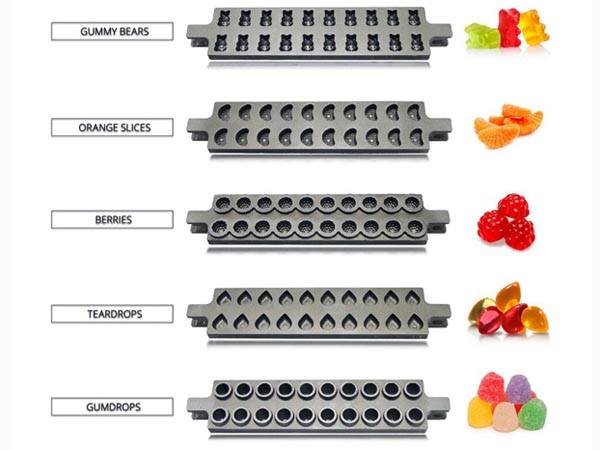

★Different shaped candies can be made via change-over of the

★Optional choice of extra chocolate paste injection system for making chocolate-central filled candies.

★The standard production capacity is from 150kg/h to 1200kg/h;

★Optional (mass) flowing controlled by Frequency inverters;

★In-line injection, dosing and pre-mixing techniques for the proportional addition of liquid;

★butterscotch" "sugar free" hard candies etc. can be made.

★Moulds can be made according to the candy samples provided by the customer

Flow of gummy production line

Raw material dissolving Transporting->Storage->Dosing—Preheating —Micro-film cooking Discharging -> Mixing with flavor and color -> Depositing -> Cooling — Demoulding — Conveying->Packing

Main machine of gummy production line

Continuous vacuum cooker

Main components: syrup pump, heater, syrup inlet, secondary steam discharge system, needle valve, vacuum steam chamber, discharge control system, rotary pot, vacuum system.

The jacketed cooking kettle is used to dissolve and cook ingredients such as glucose, granulated sugar, and water. It uses electric heating and features a large heating area, heating uniformity, and easy to control the temperature. This equipment improves product quality and shortens the processing time.

Working principle:

The purpose of boiling sugar is to remove most of the water in the sugar solution after melting sugar, so that the sugar paste eventually reaches a high concentration and retains less water. To turn the sugar solution into a thick sugar paste, this concentration must be increased by boiling evaporation process which increases the temperature gradient. This process is achieved through continuous boiling processing, so it is called boiling sugar. The water in the sugar solution needs to escape from the liquid level into the space and be eliminated. The faster the escape speed, the faster the boiling speed. Under the vacuum condition, the sugar liquid can be boiled and evaporated at a low temperature. The evaporation speed is fast and the product quality is good. Operating procedure: The process of vacuum boiling sugar is generally divided into preheating, evaporation and vacuum concentration three stages. The preheating stage is to increase the temperature and concentration of sugar solution and shorten the cycle of vacuum boiling sugar. During the evaporation stage, the remaining water in the sugar solution is removed.

Sugar boiling equipment is actually a set of evaporation and concentration equipment. The function of the heater is to have a proper heat source and a sufficient heat transfer area to heat the sugar liquid to boiling state. The evaporator can quickly remove water from the sugar liquid under boiling state, and the pump can stably transport the sugar liquid through the whole process to achieve continuous balanced production.

The production line manufactures candies in a variety of shapes using different molds. We will design molds according to your needs.

depositing die forming machine.

Main components: conveyor belt, model plate, sugar nozzle, sugar pump, storage tank, cooling device.

The depositing machine uses PLC to control the parameters such as temperature and depositing speed. These parameters are easy to read and set on the touch screen, while the syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

depositing mold molding can produce hard candy, do gummy candy and gummy candy, its wide range of adaptation, the need for roughly the same equipment. When the boiled sugar paste is still in the flow state during the depositing mold molding, the liquid sugar paste is quantitatively injected into the continuous running model plate, and then it is rapidly cooled and shaped, and finally separated from the model plate, and then sent to the packaging machine with the conveyor belt for packaging.

Working principle: The role of the sugar pouring pump is to push the sugar paste into the sugar filling mouth, which is made of two cylinders set, the outer cylinder is a fixed cylinder, there is a tank on the side and the storage tank through, and the hole at the bottom is connected with the sugar filling mouth. The inner cylinder is a opening and closing cylinder, and there is a connecting handle in the middle of the inner and outer circumference of the cylinder and a lever that swings from side to side. There is a small hole on the side and at the bottom of the cylinder. When swinging, the small hole at the bottom is closed with the small hole at the bottom of the outer cylinder, and the small hole on the side is connected with the hole of the storage tank, and the small hole on the bottom is connected with the hole on the side of the outer cylinder. There is a piston in the opening and closing cylinder, and when the piston moves up and down, the air can be inhaled, and the Jiang sugar paste is pressed to the sugar mouth. The piston moving distance determines the amount of sugar paste discharge. The piston moving distance can be adjusted according to the size of the sugar block. At the bottom of each pouring pump is a sugar nozzle, which equalizes the number of sugar models.

All rights reserved:ZHI YAN CANDY MACHINERY Co.,Ltd SitemapSitemap jelly candy production line Candy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production line