![]()

Adr :industrial zone, shanghai

Phone : +86 18221614363

Email : candymachinery@qq.com

Tel : +86 18221614363

processing capacity:50-1200kg/H

Application scope:gummy candy

Product introduction: The die-formed gummy candy making equipment produces gummy in a variety of shapes through the use of different molds. It is ideal for candy factories planning to mass produce different gummy candy

Die-Formed Gummy Making Equipment

Die-formed gummy making equipment

Automatic Die-formed gummy candy making equipment

TECHNICAL PARAMETERS

Output:150~1200kg/h

Speed:120-1800Pc/min

Maximum candy weight:16g

Minimum candy weight:2g

Steam Pressure:0.5-0.8Mpa

Steam Consumption:150~600kg/h

Working environment requirements:Room temperature:20-25℃ Humidify:55%

Power:12-60KW/380V

Length:16m-26

Weight:4000kg-11000kg

The die-formed gummy candy making equipment produces gummy in a variety of shapes through the use of different molds. It is ideal for candy factories planning to mass produce different gummy candy shapes and features a maximum capacity of 50-1200kg.hour. die-formed gummy making machine is equipped with an electric heating cooker to ensure an even PLC controlled heating time and temperature, ensuring the gummy is transparent and features a good taste. This advanced gummy making equipment effectively reduces material waste. Backed by extensive experience, not only do we offer customized die-formed gummy candy making equipments, but we also offer the matched molds.

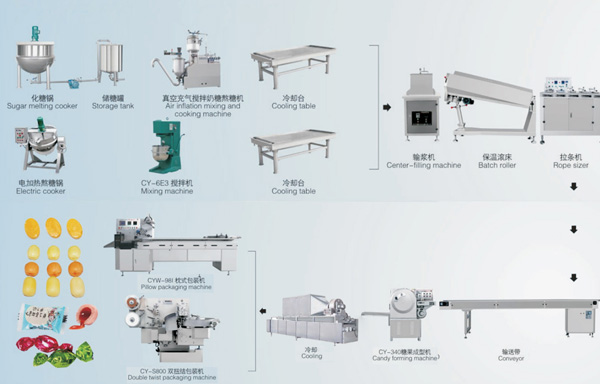

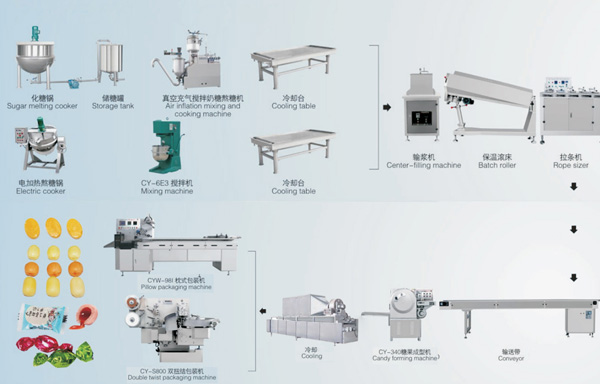

Flowchat of Automatic Die-Formed gummy making equipment

Sugar dissolving cooker-Liquid glucose storage-Continuous vacuum cooker-Cold table-Batch roller-Rope sizer-Die forming machine-Shaking distribution conveyor-Refrigerated cooler

Gummy making equipment characteristics

The heating time, heating temperature, depositing time and depositing speed are all computer controlled.

The production line is equipped with a 10.7-inch touch screen for an easy and clear display of different parameters, including the flow chart, part status, temperature, depositing speed and other parameters.

Syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

By changing molds and device components, this production line is used in the production of suckers in a variety of shapes, including spherical, flat, and 3D.

It is easy to operate and maintain.

The production line can be customized to fit your site conditions.

Main equipment of gummy making equipment

Vacuum sugar cooking machine

It features automatic temperature control, high output, time-saving, short cooking time, and can manufacture the syrup with high transparency.

①.Sugar melting cooker

Batch size(L):300

Weight(kg):280

Dimension(mm):1100*1100*1700

②.Storage tank

Batch size(L):300

Weight(kg):220

Dimension(mm):740*740*1250

③.Technical parameters

Production capacity(kg/h):350-400

Heating area(m³):2.45

Steam pressure(MPa):0.7-1.0

Steam consumption(kg/h):约about100

Syrup temperature before entering(°C):110-115

Temperature after discharging(°C):135-145

Power- Fixed displacement pump(kw):0.75

Power- Vacuum pump(kw):5.5

Dimension(mm):1900*1700*2300

Machine weight(kg):800

Heat preservation batch roller and rope sizer

Purpose

It is suitable for heat insulation and pulling of sugar pastes.

Feature

It has such features as simple operation, labor saving and high efficiency.

Technical parameters

Batch roller maximum capacity(m³):0.20

Running speed(m/min):≤40

Total power(kw):7

Weight(kg):850

Dimension(mm):(Four-wheel):4270*890*1700

Dimension(mm):(Five-wheel):4525*890*1700

All rights reserved:ZHI YAN CANDY MACHINERY Co.,Ltd SitemapSitemap jelly candy production line Candy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production line