Gummy production line Product features

Gummy production line: servo pouring control, stable and accurate pouring, equipment structure is reasonable and compact, with a degree of automation, high production efficiency. Can produce card rubber gummy candy, gelatin gummy candy, pectin gummy candy, sandwich gummy candy, fruit cake gummy candy, carrageenan gummy candy, two-color gummy candy, etc. The whole production line is composed of sandwich sugar pot, cooling mixing and storage pot, pouring machine, freezer, conveyor, roller sand machine (optional), polishing machine (optional). Added part of the equipment and template can do hard candy, lollipop, pear paste candy lollipop, etc. The candy produced by the gummy candy production line has the characteristics of crystal smooth, clear streaks of pouring candy, stable filling quantity and position, good taste and so on, and is very popular among customers.

Gummy production line Product features:

1, using PLC, more stable performance, programming automatically control vacuum sugar boiling temperature, time, insulation temperature and pouring speed;

2, 10.7 "large touch screen display process flow chart, each part of the working state, temperature pouring speed and other parameters setting, display, so that users easy to operate, master;

3, the production capacity of series products can be from 80 kg to 800 kg per hour;

4, frequency conversion speed control of the accurate flow of sugar liquid, sugar paste quality is stable;

5, dynamic mixer online complete quantitative filling and mixing of flavor, pigment and acid;

6, conveyor chain belt, cooling system, double demoulding mechanism guarantee demoulding;

7, according to the different mold can produce a variety of shapes of candy;

8, optional chocolate quantitative filling system can produce chocolate sandwich candy;

9. Replace part of the boiling device and mold. This production line can produce gummy candy, hard candy, spherical, flat three-dimensional lollipops.

Large gummy making machine

Large gummy candy production line :which can produce gummy with multiple shapes and variety colors on base of advanced technology process. It is an ideal machine to produce superior quality gummy candy of single color and double color; By change-over molds or depositors, different color and different shape of gummy can be also produced. The on-line mixer achieves the quantitative dosing and mixing of the flavor, color and acid. High degree of automation can produce super quality of gummy, at the same time it saves the manpower and the

Gummy candy making machine is developed by the R&D department of our company according to the market demand for gel gummy in various shapes and colors, using advanced production technology. It is an ideal machine for the continuous production of colloidal candies. Can produce high - quality single - color, two - color candy, single - layer candy. Can also be replaced by mold or pouring the first production of high quality, a variety of shapes, a variety of colors of gel gummy. Complete the quantitative filling and mixing of pigment and acid liquid of essence online; Highly automated production can not only produce products of consistent quality, but also save labor and occupy space, thus reducing costs.

The principle of injection molding in gummy production line: The materials that are boiled and pre-mixed are lifted by the discharge pump through the entrance of the pipeline, and pass through the outlet through the inclined plate and into the hopper insulated by the jacket. The pouring temperature of the materials is kept at 140℃. Under this temperature, the materials have good fluidity. The hopper is fixed on the pouring machine. Through the operation of the pouring machine, the material is injected quantitatively through the pouring head into the model plate. The mold plate is fixed on a circular conveyor belt in order to transfer, and the length of the belt is generally 13~14m; The die plate equipped with materials is cooled by the air flow above and below in operation. The cold air temperature after treatment is 6~8℃ and the wind speed is 7~8m/s. When the mold plate moves to the bottom and reverses, the material has solidified. When the demoulding zone is reached at 10, the sugar granules in the model are pushed on the discharge conveyor belt by the demoulding device and sent to the packaging machine.

Gummy candy is a kind of soft, sticky, watery, slightly elastic, transparent and translucent candy. The water content in gummies ranges from 7% to 24% and reducing sugar from 20% to 40%. The vast majority of gummy candies are made into fruit candy, and some are made into milk candy and cool candy. The shape is rectangular or irregular. Its main characteristic is that it contains different kinds of gel, so that the candy body has the property of gel, so it is also called gel candy. gummy is pectin as candy gel agent, its texture is tender and elastic, transparent candy, with a variety of fruit flavor.

Flow of gummy making machine

Jacket cooker-Mix tank-Lobe pump-Storage tank-Depositor-Cooling tunnel-Oil spray-bagging machine

Main machine of gummy making machine

1.Jacketed cooking kettle

The jacketed cooking kettle is used to dissolve and cook ingredients such as glucose, granulated sugar, and water. It uses electric heating and features a large heating area, heating uniformity, and easy to control the temperature. This equipment improves product quality and shortens the processing time.

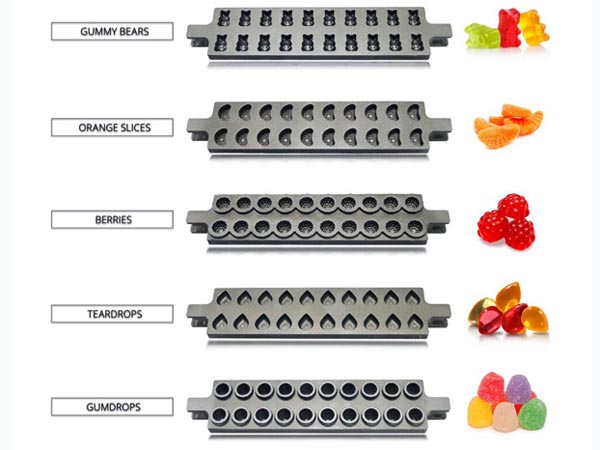

Gummy mold

The production line manufactures candies in a variety of shapes using different molds. We will design molds according to your needs.

Gummy Depositing machine

The depositing machine uses PLC to control the parameters such as temperature and depositing speed. These parameters are easy to read and set on the touch screen, while the syrup flow is precisely controlled via a frequency control system to ensure a stable sugar paste quality.

Gummy cooling tunnel is an efficient and energy-saving fast cooling equipment designed for gummy cooling. It has the characteristics of good cooling effect, fast speed and low noise. This gummy cooling equipment adopts a new process to cool and deliver candy. Therefore, a more uniform cooling effect is provided for the candy in the cooling conveying process to prevent the candy from changing and cracking during the cooling process. At the same time, the oscillating mode effectively prevents the candy from sticking to each other and sticking to the oscillating plate. The unique closed super quiet design fully conforms to environmental standards, is the most suitable for gummy stamping molding production line cooling equipment.

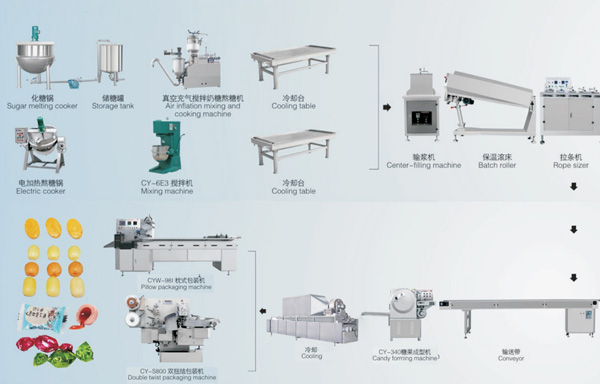

Die-formed Gummy Candy Production Line

Gummy Candy Making machiine

This line can produce all kinds of die-formed hard boild candy.

Automatic Die-formed Gummy Candy Production Line can produce all kinds of Gummy Candy, solid Gummy Candy, filled Gummy Candy, shaped Gummy Candy, color Gummy Candy and other Gummy Candy

Continuously vacuum cooker, guarantee the quality of sugar masses.

Special forming style is better for central-filling.

Production capacity can be from 200 to 1000kg/h.

Sanitary structure designed.

The central filler, rope sizer and former work together available.

Different candy shape can be made depend upon changing of the mould.

A better effect of cooling is available by the conveying and cooling system.

Lollipop can be made when the lollipop former is set instead of Gummy Candy former.

Technological process of Die-formed Gummy Candy Production Line

Sugar melting cooker-Storage tank-Vacuum sugar cooking machine-Cooling table-Center filling machine-Batch roller-Rope sizer-Candy forming machine-Cooling sifter-packaging machine

1.How to improve the production efficiency of gummy candy production line

The production efficiency of a gummy candy production line refers to the number of candies produced per unit time. Increasing production efficiency allows more sweets to be produced in the same amount of time, thereby increasing production, reducing costs and improving competitiveness. The following will discuss how to improve the production efficiency of gummy production line from the aspects of technology improvement, process optimization and personnel training.

First, technological improvement

Update equipment: The use of excellent gummy candy production equipment, with automation, multi-function and adjustability, can improve the overall efficiency of the production line.

The use of machine vision technology: by installing a machine vision system on the production line to detect and sort gummy candy, such as color, shape, size and other characteristics, can improve the detection efficiency and accuracy.

Second, process optimization

Production line layout optimization: According to production requirements and process flow, rationally arrange equipment and workstations on the production line, shorten the transportation and handling time of materials, reduce waiting and traffic time, and improve production efficiency.

Increase parallel processes: Separate processes that can be carried out in parallel, and set up multiple parallel workstations to avoid bottlenecks and constraints and speed up production.

Data analysis tracking: Through data collection and analysis, understand the bottlenecks on the production line and the causes of low production efficiency, and make targeted improvements.

2.In the cooling tunnel stage of confectionery equipment, some key technologies and processing processes are involved.

Here's a breakdown of what's going on:

1. Technical introduction of cooling tunnel:

What it does: The cooling tunnel is used to quickly cool the just-formed candy to solidify its structure and ensure the quality and shape of the candy.

Structure: A cooling tunnel usually consists of one or more conveyor belts with upper and side cooling devices such as air coolers, water coolers or refrigeration units.

Control systems: Modern cooling tunnels are often equipped with automated control systems that monitor and adjust parameters such as conveyor belt speed, cooling temperature and humidity for precise control.

3.Key parameters of boiling temperature of confectionery equipment

The key parameters of sugar boiling temperature of confectionery equipment include sugar boiling temperature, sugar boiling material ratio and sugar boiling time. Here is an introduction to these parameters:

Boiling temperature:

Function: Boiling temperature refers to the temperature required to heat the raw material to the melting state. Controlling the boiling temperature can affect the viscosity, fluidity of the syrup and the rate of evaporation of water in the syrup, which affects the taste and texture of the final candy.

Common range: The boiling temperature is usually between 110°C and 120°C, but the specific temperature depends on the type and formula of confectionery being produced.

Temperature control: Sugar boiling equipment is usually equipped with a temperature control system that can precisely control the heating temperature of the syrup to ensure that the syrup reaches the required concentration and viscosity.

Vitamin jelly gummy sugar syrup temperature at the time of adding vitamin

The temperature that vitamin can withstand is 70 degrees Celsius, so the liquid temperature of vitamin gummy sugar and gel after melting should not exceed 60 degrees. Vitamin is an antioxidant substance, which helps to maintain the basic energy needed for human life activities, and vitamin is also an enzyme substance, but any enzyme substance may be damaged in the case of too high temperature. Under normal circumstances, the temperature exceeds 60 degrees will occur damage, more than 80 degrees in the case of damage is irreversible, the daily storage temperature should not exceed 25 degrees.

Vitamin is usually a water-soluble vitamin, but its properties are not very good, so in the high temperature environment above 70 degrees Celsius, usually the vitamin will decompose and deteriorate, easy to be destroyed, such as boiled vegetables, it will destroy the vitamins contained in vegetables.

Therefore, after our sugar pot and then add vitamins to the mixing equipment, the temperature at this time is controlled at 50-60 degrees, this time the vitamin will not lose activity, and it does not affect the candy deposting machine after the gummy candy deposting

Start Your Perfect Gummy Candy Production As a world-class candy production line manufacturer, We can perfectly provide the production line and production advice required for Toffee production. If you have any needs, you can visit our gummy production line website to get the latest product consultation and complete solutions. Contact us immediately to communicate with our professional technical team.